The evolution of industrial electronics has brought forth remarkable innovations that continue to reshape how we approach power management and electromagnetic applications. Among these breakthrough technologies, nanocrystalline cores have emerged as a game-changing solution for manufacturers seeking superior performance in transformers, inductors, and other magnetic components. These advanced magnetic materials offer exceptional properties that traditional ferrite and silicon steel cores simply cannot match, making them increasingly essential in modern industrial applications where efficiency, reliability, and compact design are paramount.

The unique crystalline structure of these magnetic cores provides distinct advantages across various industrial sectors, from renewable energy systems to high-frequency power supplies. Understanding the fundamental benefits of nanocrystalline technology enables engineers and procurement professionals to make informed decisions that can significantly impact system performance and operational costs. This comprehensive analysis explores the critical advantages that position nanocrystalline cores as the preferred choice for demanding industrial electronics applications.

Superior Magnetic Properties and Performance Characteristics

Exceptional Permeability and Saturation Performance

Nanocrystalline cores exhibit remarkably high initial permeability values, typically ranging from 80,000 to 150,000, which far exceeds conventional ferrite materials. This exceptional permeability enables the design of more compact magnetic components while maintaining superior inductance characteristics. The high saturation flux density, reaching up to 1.2 Tesla, allows these cores to handle higher power levels without experiencing magnetic saturation, making them ideal for high-performance transformers and inductors in industrial power systems.

The stable permeability across wide frequency ranges ensures consistent performance in applications spanning from 50 Hz power transformers to high-frequency switching power supplies operating at several hundred kilohertz. This frequency stability eliminates the need for complex compensation circuits and reduces design complexity while improving overall system reliability. Engineers particularly value this characteristic when designing precision measurement equipment and sensitive industrial control systems where magnetic stability is crucial.

Ultra-Low Core Losses for Enhanced Efficiency

One of the most significant advantages of nanocrystalline cores lies in their exceptionally low core losses, which can be up to 80% lower than conventional silicon steel cores at equivalent operating conditions. These reduced losses translate directly into improved energy efficiency, reduced heat generation, and lower operating costs over the system's lifetime. In industrial applications where continuous operation is required, this efficiency improvement can result in substantial energy savings and reduced cooling requirements.

The low loss characteristics remain consistent across varying temperature conditions, ensuring reliable performance in challenging industrial environments. This thermal stability is particularly beneficial in outdoor installations, manufacturing facilities with high ambient temperatures, and applications where thermal management is a critical design constraint. The reduced heat generation also contributes to extended component lifespan and improved system reliability.

Design Flexibility and Manufacturing Advantages

Compact Form Factors and Weight Reduction

The superior magnetic properties of nanocrystalline cores enable significant size and weight reductions in magnetic component designs. Engineers can achieve the same magnetic performance with cores that are 30-50% smaller and lighter than traditional alternatives. This space efficiency is particularly valuable in applications where installation space is limited, such as renewable energy inverters, electric vehicle charging stations, and compact industrial power supplies.

The reduced physical footprint allows for more flexible system layouts and can contribute to overall cost savings through reduced enclosure sizes and simplified mechanical mounting requirements. In mobile and portable industrial equipment, the weight reduction provided by nanocrystalline cores can improve operational efficiency and reduce transportation costs while maintaining superior electrical performance.

Enhanced Design Tolerance and Manufacturing Consistency

Nanocrystalline cores offer excellent manufacturing consistency with tight tolerances on magnetic properties, enabling more predictable design outcomes and reduced production variability. This consistency is particularly important in high-volume manufacturing environments where component uniformity directly impacts product quality and production efficiency. The material's stability during processing and assembly operations reduces the risk of magnetic property degradation during manufacturing.

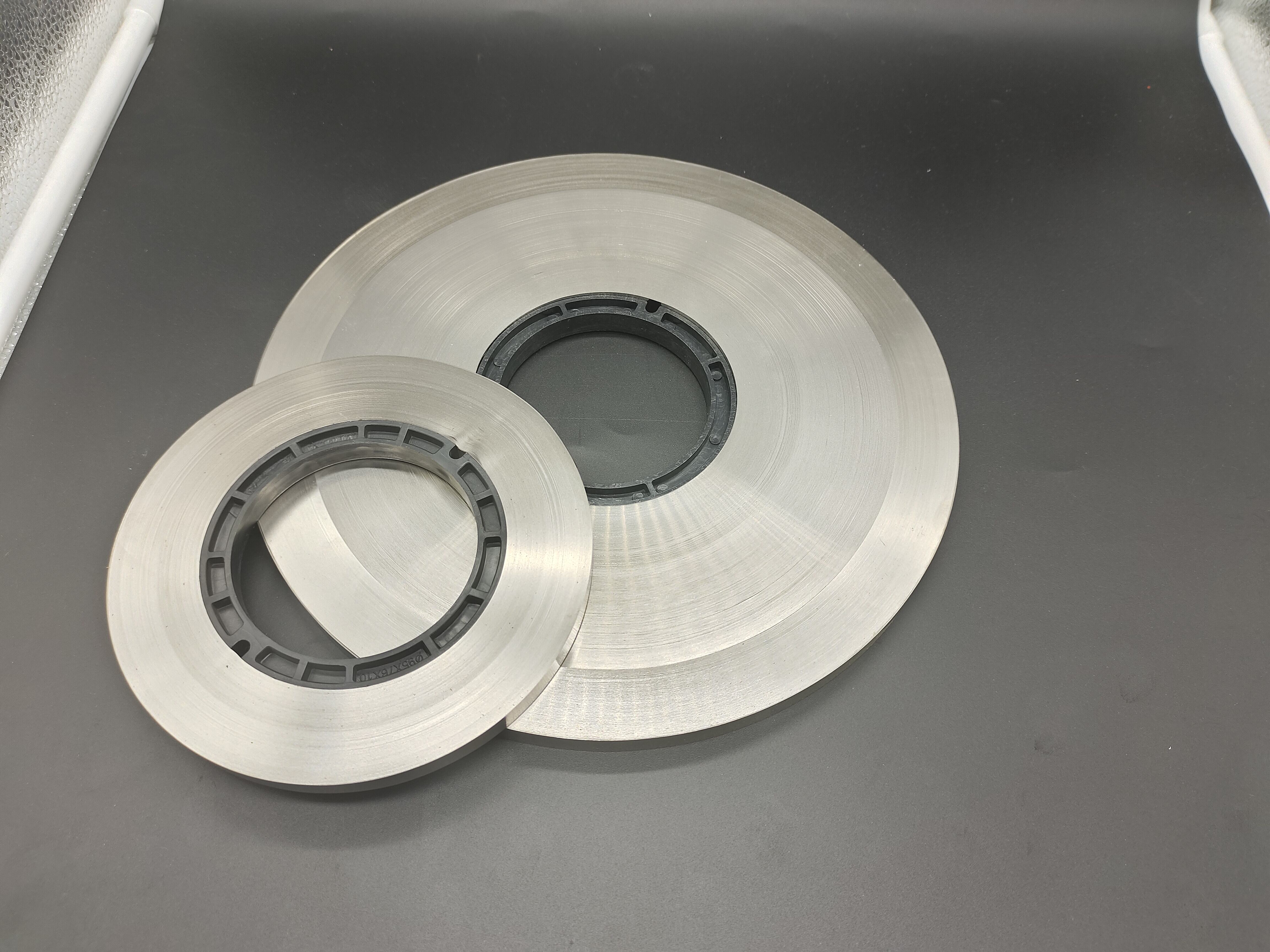

The cores can be manufactured in various shapes and sizes to meet specific application requirements, including toroidal, C-cores, E-cores, and custom geometries. This design flexibility allows engineers to optimize magnetic circuits for specific performance criteria while maintaining manufacturing feasibility. The ability to achieve precise air gap control and consistent winding arrangements further enhances the repeatability of magnetic component production.

Application-Specific Benefits Across Industrial Sectors

Power Electronics and Renewable Energy Systems

In renewable energy applications, nanocrystalline cores provide exceptional performance in inverter transformers, filter inductors, and power factor correction circuits. The high-frequency capability and low losses make these cores particularly suitable for modern grid-tie inverters and energy storage systems where efficiency directly impacts system economics. Solar inverter manufacturers benefit from the cores' ability to maintain consistent performance across varying environmental conditions and load profiles.

Wind power applications leverage the cores' superior magnetic properties in generator designs and power conditioning equipment. The reduced core losses contribute to improved overall system efficiency, while the compact design enables more efficient nacelle layouts and reduced tower loading. Electric vehicle charging infrastructure also benefits from nanocrystalline cores through improved power density and thermal management in high-power charging stations.

Industrial Automation and Control Systems

Industrial automation systems require precise and reliable magnetic components for motor drives, servo amplifiers, and control transformers. Nanocrystalline cores provide the stable magnetic characteristics necessary for accurate current sensing, precise motor control, and reliable signal isolation. The low noise characteristics of these cores contribute to improved electromagnetic compatibility in sensitive industrial control environments.

Manufacturing equipment benefits from the cores' ability to maintain performance consistency over extended operating periods with minimal drift in magnetic properties. This stability is crucial in precision manufacturing processes where even small variations in control system performance can impact product quality. The reduced maintenance requirements and extended operational life of nanocrystalline cores contribute to improved manufacturing uptime and reduced lifecycle costs.

Economic and Environmental Considerations

Lifecycle Cost Advantages and Return on Investment

While nanocrystalline cores may have higher initial costs compared to conventional materials, the total cost of ownership typically favors these advanced materials due to improved efficiency, reduced cooling requirements, and extended operational life. Energy savings from reduced core losses can provide significant cost benefits over the system's operational lifetime, particularly in applications with high duty cycles or continuous operation requirements.

The improved reliability and reduced maintenance requirements of nanocrystalline cores contribute to lower lifecycle costs through reduced downtime and service interventions. Industrial facilities benefit from improved system availability and reduced maintenance scheduling requirements. The compact design also enables cost savings through reduced installation space requirements and simplified cooling system designs.

Environmental Impact and Sustainability Benefits

The enhanced efficiency of nanocrystalline cores directly contributes to reduced energy consumption and lower carbon emissions in industrial applications. This environmental benefit aligns with corporate sustainability goals and regulatory requirements for energy efficiency. The longer operational life of these cores also reduces material consumption and waste generation over time, supporting circular economy principles in industrial equipment design.

Manufacturing processes for nanocrystalline cores have become increasingly environmentally friendly, with reduced material waste and energy consumption during production. The recyclability of these materials at end-of-life further enhances their environmental profile compared to traditional magnetic materials that may contain rare earth elements or other environmentally challenging materials.

FAQ

What applications benefit most from nanocrystalline cores

Nanocrystalline cores provide the greatest benefits in high-frequency applications such as switching power supplies, inverters, and filter inductors where their low core losses and high permeability significantly improve efficiency. They are particularly valuable in renewable energy systems, electric vehicle charging infrastructure, and precision industrial control equipment where performance consistency and reliability are critical requirements.

How do nanocrystalline cores compare to ferrite cores in terms of performance

Nanocrystalline cores offer superior permeability, lower core losses, and better temperature stability compared to ferrite cores. While ferrite cores remain cost-effective for many applications, nanocrystalline cores provide significant performance advantages in demanding applications where efficiency, size reduction, and thermal performance are priorities. The choice depends on specific application requirements and performance versus cost considerations.

What are the temperature limitations of nanocrystalline cores

Most nanocrystalline cores can operate effectively at temperatures up to 130-150°C, with some specialized grades capable of higher temperature operation. The cores maintain stable magnetic properties across their rated temperature range, making them suitable for most industrial applications. Proper thermal design and heat dissipation considerations ensure optimal performance within these temperature limits.

Are there any design considerations specific to nanocrystalline cores

Design considerations include proper handling during assembly to maintain magnetic properties, appropriate winding techniques to minimize stress on the core material, and consideration of the cores' high permeability when designing magnetic circuits. Air gap requirements may differ from conventional materials, and the cores' sensitivity to mechanical stress should be considered in mounting and enclosure design to ensure optimal long-term performance.