Selecting the proper step-down transformer for voltage conversion is a critical decision that can significantly impact the performance, safety, and longevity of your electrical systems. Whether you're working on industrial equipment, commercial applications, or specialized electronic devices, understanding the fundamental principles of voltage reduction ensures optimal operation and prevents costly equipment failures. The process involves evaluating multiple technical parameters, load requirements, and environmental factors that directly influence transformer performance. Modern electrical systems demand precise voltage control, making the selection of appropriate step-down transformers essential for maintaining system integrity and operational efficiency.

Understanding Step-Down Transformer Fundamentals

Basic Operating Principles

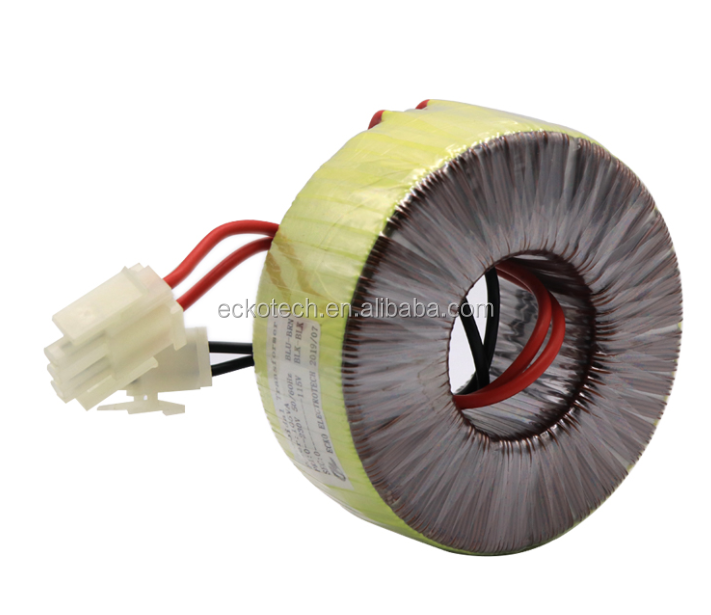

A step-down transformer operates on the principle of electromagnetic induction, utilizing two or more coils wound around a magnetic core to reduce voltage levels from primary to secondary windings. The transformer ratio determines the voltage reduction capability, with the secondary winding having fewer turns than the primary winding. This configuration enables safe voltage conversion from higher input levels to lower output voltages suitable for specific applications. The magnetic flux created in the primary winding induces voltage in the secondary winding, with the turns ratio directly proportional to the voltage transformation ratio.

The efficiency of step-down transformers depends on core material quality, winding design, and operating frequency characteristics. Silicon steel cores provide excellent magnetic properties for power frequency applications, while ferrite cores offer superior performance for higher frequency operations. Understanding these fundamental principles helps engineers select transformers that match specific application requirements while maintaining optimal efficiency and minimal losses.

Voltage Transformation Characteristics

Voltage transformation in step-down transformers follows the relationship where output voltage equals input voltage multiplied by the turns ratio. This mathematical relationship provides the foundation for determining appropriate transformer specifications based on required voltage levels. The transformation process maintains power conservation principles, meaning that as voltage decreases, current proportionally increases to maintain power balance across the transformer.

Understanding voltage regulation characteristics becomes crucial when selecting transformers for applications with varying load conditions. Voltage regulation describes how well a transformer maintains stable output voltage under different loading scenarios. High-quality transformers exhibit minimal voltage variation across their operating range, ensuring consistent performance for sensitive electronic equipment and industrial machinery.

Key Selection Criteria and Specifications

Power Rating and Load Requirements

Determining the appropriate power rating represents the most critical aspect of transformer selection, requiring careful analysis of connected load characteristics and future expansion requirements. The transformer's VA (volt-ampere) rating must exceed the total connected load by an appropriate safety margin, typically 25-30% for continuous operation. This margin accounts for load variations, starting currents, and potential system expansion while preventing transformer overheating and premature failure.

Load type significantly influences transformer selection, with resistive, inductive, and capacitive loads presenting different operational challenges. Inductive loads such as motors require higher starting currents, necessitating transformers with adequate short-term overload capacity. Capacitive loads can cause leading power factors that affect transformer performance and efficiency. Understanding these load characteristics ensures proper transformer sizing and optimal system performance.

Environmental and Installation Considerations

Environmental factors play a crucial role in transformer selection, with temperature, humidity, altitude, and ambient conditions directly affecting operational parameters and service life. High-temperature environments require transformers with enhanced cooling systems or higher temperature-rated insulation materials. Humidity levels influence insulation integrity and corona discharge characteristics, particularly in outdoor or industrial installations.

Installation location constraints affect transformer configuration choices, with indoor, outdoor, and hazardous area applications requiring different enclosure types and protection levels. Ventilation requirements, accessibility for maintenance, and local electrical codes influence transformer selection and installation design. Proper consideration of these factors ensures reliable operation and compliance with safety regulations.

Technical Performance Parameters

Efficiency and Loss Characteristics

Transformer efficiency directly impacts operational costs and system performance, making it a critical selection criterion for energy-conscious applications. Modern step-down transformer designs achieve efficiencies exceeding 95% through advanced core materials, optimized winding configurations, and improved manufacturing techniques. Core losses and copper losses represent the primary efficiency limitations, with core losses remaining relatively constant while copper losses vary with load current.

Understanding loss characteristics helps optimize transformer selection for specific operating profiles and duty cycles. Continuous operation applications benefit from high-efficiency designs that minimize heat generation and reduce cooling requirements. Variable load applications may require different efficiency optimization strategies that balance performance across the operating range while maintaining acceptable loss levels during peak demand periods.

Regulation and Impedance Specifications

Voltage regulation characteristics determine how well a transformer maintains stable output voltage under varying load conditions, with typical regulation values ranging from 2% to 8% for standard industrial transformers. Low regulation values indicate better voltage stability and improved performance for voltage-sensitive loads. Impedance specifications affect fault current levels, system stability, and parallel operation capabilities when multiple transformers serve common loads.

Short-circuit impedance influences fault current magnitude and protective device coordination, making it essential for system protection design. Higher impedance values limit fault currents but may cause greater voltage drops under normal operating conditions. Balancing these competing requirements requires careful analysis of system protection requirements and load sensitivity to voltage variations.

Application-Specific Selection Guidelines

Industrial and Commercial Applications

Industrial applications often require robust transformer designs capable of handling harsh environmental conditions, frequent load variations, and extended operational periods. Step-down transformers serving industrial machinery must accommodate motor starting currents, harmonic distortion from variable frequency drives, and potential overload conditions. Selecting transformers with appropriate overload ratings and harmonic tolerance ensures reliable operation in demanding industrial environments.

Commercial applications typically emphasize energy efficiency, compact design, and quiet operation characteristics. Office buildings, retail facilities, and commercial complexes benefit from transformers optimized for stable loads with predictable operating patterns. Noise levels become particularly important in occupied spaces, requiring careful consideration of transformer mounting methods and acoustic isolation techniques.

Specialized Electronic and Control Systems

Electronic systems require transformers with exceptional voltage stability, low harmonic distortion, and minimal electromagnetic interference characteristics. Control circuits, instrumentation, and sensitive electronic equipment demand transformers designed specifically for low-voltage, high-precision applications. These specialized transformers often incorporate electrostatic shielding, precision winding techniques, and superior insulation materials to ensure optimal performance.

Medical equipment, laboratory instrumentation, and communication systems represent applications where transformer performance directly affects system accuracy and reliability. Ultra-low noise designs, medical-grade isolation, and compliance with specialized safety standards become essential selection criteria for these critical applications. Understanding specific industry requirements ensures proper transformer specification and regulatory compliance.

Installation and Safety Considerations

Electrical Code Compliance and Safety Standards

Proper transformer selection must consider applicable electrical codes, safety standards, and regulatory requirements that govern installation and operation. National Electrical Code (NEC) provisions specify minimum clearances, overcurrent protection, grounding requirements, and installation methods for different transformer types and applications. Understanding these requirements during the selection phase prevents costly modifications and ensures code-compliant installations.

Safety standards such as UL, IEEE, and IEC specifications define performance criteria, testing requirements, and certification processes for transformer products. Selecting transformers that meet or exceed applicable safety standards provides assurance of product quality and regulatory compliance. Documentation requirements for safety certifications become particularly important for commercial and industrial installations subject to inspection and approval processes.

Maintenance and Serviceability Requirements

Long-term reliability depends on proper maintenance access and serviceability design features that facilitate routine inspection and preventive maintenance activities. Transformer selection should consider maintenance requirements, replacement part availability, and service support from manufacturers. Designs that incorporate accessible connection points, removable covers, and standard replacement components reduce maintenance costs and system downtime.

Monitoring and diagnostic capabilities enhance transformer reliability through early detection of potential problems and performance degradation. Modern transformers may incorporate temperature monitoring, load tracking, and condition assessment features that support predictive maintenance programs. These advanced capabilities justify higher initial costs through reduced maintenance expenses and improved system availability.

FAQ

What factors determine the required VA rating for a step-down transformer?

The required VA rating depends on the total connected load, load type characteristics, and safety margin requirements. Calculate the sum of all connected loads, then add 25-30% safety margin for continuous operation. Consider starting currents for motors, power factor correction requirements, and potential future load expansion. Inductive loads may require higher VA ratings due to reactive power requirements, while resistive loads typically match their power consumption directly.

How does ambient temperature affect transformer selection and performance?

Ambient temperature directly influences transformer current-carrying capacity and service life through its effect on insulation temperature rise. Higher ambient temperatures reduce allowable load levels and may require derating calculations or enhanced cooling systems. Most transformers are rated for 40°C ambient temperature, with temperature correction factors applied for different operating conditions. Extreme temperature environments may require special insulation classes or cooling system modifications.

What are the key differences between dry-type and oil-filled step-down transformers?

Dry-type transformers use air or solid insulation materials and are suitable for indoor applications where fire safety is paramount. They require less maintenance but have lower power density and higher operating temperatures. Oil-filled transformers offer better cooling characteristics and higher power ratings but require containment systems and regular oil testing. Selection depends on installation location, environmental requirements, maintenance capabilities, and local fire codes.

How do harmonics affect step-down transformer selection and sizing?

Harmonic distortion from nonlinear loads increases transformer losses and heating, potentially requiring oversized transformers or specialized designs. Variable frequency drives, switching power supplies, and LED lighting create harmonic currents that cause additional losses in transformer windings and core materials. K-factor rated transformers are designed to handle harmonic loads, with higher K-factors indicating greater harmonic tolerance. Proper harmonic analysis ensures adequate transformer capacity and prevents overheating issues.

Table of Contents

- Understanding Step-Down Transformer Fundamentals

- Key Selection Criteria and Specifications

- Technical Performance Parameters

- Application-Specific Selection Guidelines

- Installation and Safety Considerations

-

FAQ

- What factors determine the required VA rating for a step-down transformer?

- How does ambient temperature affect transformer selection and performance?

- What are the key differences between dry-type and oil-filled step-down transformers?

- How do harmonics affect step-down transformer selection and sizing?