Medical device performance depends heavily on electrical safety and signal integrity, making isolation transformers a critical component in healthcare technology. These specialized electrical devices provide galvanic isolation between input and output circuits, protecting both patients and equipment from potentially dangerous electrical faults. In medical environments where precision and safety are paramount, isolation transformers serve as the first line of defense against electrical hazards while simultaneously enhancing device functionality and reliability.

The healthcare industry operates under stringent electrical safety standards that require medical devices to maintain complete electrical isolation from ground potential. Modern medical facilities rely on sophisticated diagnostic and therapeutic equipment that must function flawlessly while protecting patients from electrical shock. Isolation transformers meet these demanding requirements by creating an electrical barrier that prevents current leakage and eliminates ground loops that could compromise device performance.

Understanding Isolation Transformer Technology in Medical Applications

Fundamental Operating Principles

Isolation transformers operate on the principle of electromagnetic induction without direct electrical connection between primary and secondary windings. This design creates complete galvanic isolation, meaning no physical conductive path exists between input and output circuits. The magnetic coupling transfers energy while maintaining electrical separation, which is essential for medical device safety standards.

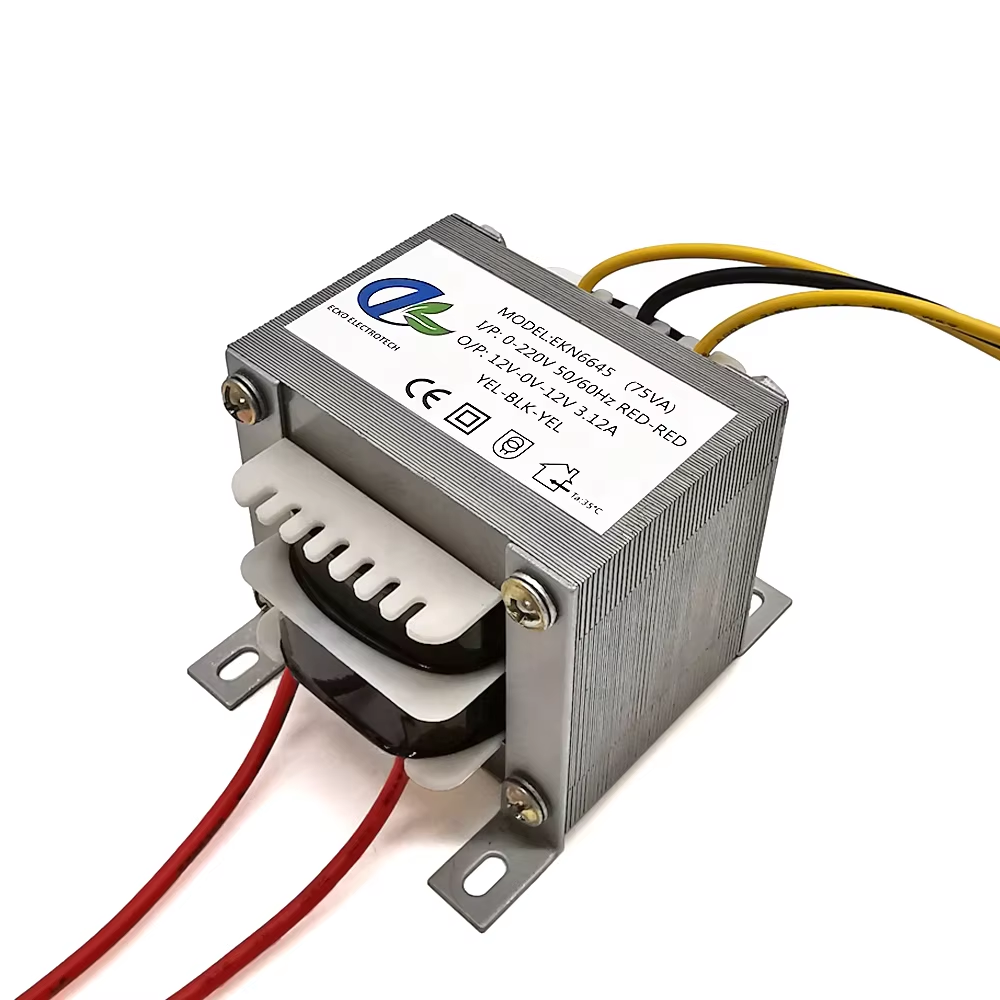

The transformer core material and winding configuration determine the isolation effectiveness and power transfer efficiency. Medical-grade isolation transformers typically feature high-permeability ferrite or laminated steel cores that minimize losses while maximizing isolation performance. The winding arrangement includes multiple insulation layers and specific spacing requirements to achieve the isolation voltages required by medical safety standards.

Safety Standards and Compliance Requirements

Medical isolation transformers must comply with IEC 60601-1 standards, which specify requirements for basic safety and essential performance of medical electrical equipment. These standards mandate specific isolation voltages, leakage current limits, and insulation resistance values that ensure patient and operator safety. Compliance testing includes dielectric strength verification, insulation resistance measurement, and leakage current analysis under various operating conditions.

The UL 2601-1 standard provides additional requirements for medical equipment used in North American markets. These standards work together to establish comprehensive safety protocols that govern the design, testing, and certification of medical isolation transformers. Manufacturers must document compliance through rigorous testing procedures and maintain quality management systems that ensure consistent performance across production runs.

Enhanced Patient Safety Through Electrical Isolation

Prevention of Electrical Shock Hazards

Patient safety represents the primary benefit of using isolation transformers in medical devices. Direct connection to mains power creates potential shock hazards, especially when patients have reduced skin resistance due to moisture or medical procedures. Isolation transformers eliminate this risk by preventing any direct electrical path between the patient and ground potential.

The isolation barrier also protects against equipment faults that could otherwise energize exposed metal surfaces. Even if insulation failure occurs within the medical device, the isolation transformer prevents dangerous voltages from reaching patient contact areas. This protection is particularly critical for devices that make direct electrical contact with patients, such as ECG monitors, defibrillators, and surgical equipment.

Reduction of Leakage Current

Medical devices must maintain leakage current levels below specific thresholds to ensure patient safety. Isolation transformers significantly reduce leakage current by eliminating the direct connection between device circuits and ground. This reduction is especially important for patient-applied parts that have direct contact with the body.

The transformer design includes specific insulation materials and construction techniques that minimize capacitive coupling between windings. Advanced designs incorporate electrostatic shields that further reduce leakage current while maintaining isolation performance. Regular testing and calibration ensure that leakage current levels remain within acceptable limits throughout the device's operational lifetime.

Improved Signal Integrity and Performance

Elimination of Ground Loop Interference

Ground loops create significant interference problems in medical devices, particularly those processing low-level biological signals. These loops occur when multiple grounding paths exist between interconnected equipment, creating circulating currents that introduce noise and distortion. Isolation transformers break these ground loops by providing complete galvanic isolation between input and output circuits.

The isolation barrier prevents ground potential differences from affecting device performance, which is crucial for sensitive measurement equipment. ECG machines, EEG monitors, and other diagnostic devices rely on accurate signal acquisition that can be compromised by ground-related interference. Isolation transformers ensure that these devices maintain their specified accuracy and sensitivity levels.

Noise Reduction and EMC Performance

Electromagnetic compatibility requirements for medical devices have become increasingly stringent as healthcare facilities incorporate more electronic equipment. Isolation transformers provide inherent filtering characteristics that attenuate high-frequency noise and electromagnetic interference. The magnetic coupling naturally blocks common-mode noise while preserving the desired signal components.

Advanced isolation transformer designs include integrated filtering components that enhance EMC performance beyond basic isolation requirements. These features help medical devices meet both emission and immunity standards while maintaining optimal performance in electrically noisy environments. The result is improved device reliability and reduced susceptibility to interference from other equipment.

Power Quality Enhancement in Healthcare Facilities

Voltage Regulation and Stability

Healthcare facilities often experience power quality issues that can affect medical device performance. Voltage fluctuations, harmonics, and transients can cause equipment malfunctions or reduced accuracy in critical applications. Isolation transformers with proper design characteristics can provide voltage regulation and power conditioning that stabilizes the supply to sensitive medical equipment.

The transformer impedance characteristics help filter out voltage spikes and provide some degree of voltage regulation under varying load conditions. This stabilization is particularly important for devices that require precise operating voltages, such as imaging equipment and laboratory analyzers. Consistent power supply quality translates directly into improved device performance and reliability.

Harmonic Filtering and Power Factor Correction

Modern medical devices increasingly incorporate switched-mode power supplies and other nonlinear loads that generate harmonic distortion. These harmonics can interfere with other equipment and reduce overall power system efficiency. Specially designed isolation transformers can provide harmonic filtering that reduces distortion levels and improves power factor.

The filtering action occurs through the transformer's inherent inductance and can be enhanced with additional components integrated into the transformer design. This approach provides both isolation and power quality improvement in a single component, simplifying system design while reducing overall costs. The result is improved facility-wide power quality that benefits all connected equipment.

Reliability and Maintenance Advantages

Extended Equipment Lifespan

Isolation transformers contribute to extended medical device lifespan by protecting internal components from power system disturbances. Voltage transients, surges, and other power quality issues can cause cumulative damage to sensitive electronic components over time. The isolation barrier and inherent filtering characteristics of isolation transformers reduce stress on downstream components.

This protection is particularly valuable for expensive medical equipment where premature failure results in significant replacement costs and potential service disruptions. The improved reliability translates into reduced maintenance requirements and lower total cost of ownership over the equipment's operational lifetime. Healthcare facilities benefit from more predictable equipment performance and reduced unexpected downtime.

Simplified Troubleshooting and Maintenance

The isolation provided by transformers simplifies troubleshooting procedures by eliminating ground-related issues that can mask other problems. Technicians can work more safely on isolated equipment, and diagnostic procedures are less likely to be affected by grounding complications. This simplification reduces maintenance time and improves the accuracy of fault diagnosis.

Isolation transformers also provide a convenient isolation point for equipment testing and calibration. The ability to completely isolate a device from the main power system allows for more comprehensive testing procedures and reduces the risk of equipment damage during maintenance activities. This capability is particularly valuable in critical care environments where equipment downtime must be minimized.

FAQ

What safety standards must medical isolation transformers meet

Medical isolation transformers must comply with IEC 60601-1 international standards and UL 2601-1 North American standards. These standards specify requirements for isolation voltage, leakage current limits, insulation resistance, and dielectric strength. Compliance includes rigorous testing for patient safety under normal and fault conditions, with specific requirements varying based on the type of medical device and its intended application.

How do isolation transformers improve medical device accuracy

Isolation transformers improve medical device accuracy by eliminating ground loops and reducing electromagnetic interference that can corrupt sensitive biological signals. The galvanic isolation prevents ground potential differences from affecting measurements, while the transformer's inherent filtering characteristics attenuate high-frequency noise. This results in cleaner signals and more accurate readings from diagnostic equipment like ECG monitors and patient monitoring systems.

Can isolation transformers reduce maintenance costs for medical equipment

Yes, isolation transformers can significantly reduce maintenance costs by protecting medical equipment from power quality issues that cause component stress and premature failure. The isolation barrier shields sensitive electronics from voltage transients, surges, and other disturbances that accumulate damage over time. This protection extends equipment lifespan, reduces unexpected failures, and simplifies troubleshooting procedures, resulting in lower total cost of ownership.

What power ratings are available for medical isolation transformers

Medical isolation transformers are available in a wide range of power ratings from a few watts for portable devices up to several kilowatts for large imaging systems and surgical equipment. Common ratings include 50VA to 10kVA for most medical applications, with custom designs available for specialized requirements. The selection depends on the specific medical device's power consumption, safety requirements, and installation constraints within the healthcare facility.