Essential Factors in Power Transformer Selection

Selecting the right power transformer is a critical decision that impacts the efficiency, reliability, and safety of your entire electrical system. Whether you're working on an industrial facility, commercial building, or utility-scale project, understanding the key considerations in transformer selection can mean the difference between optimal performance and costly failures.

Power transformers serve as the backbone of electrical distribution systems, converting voltage levels to ensure efficient power transmission and safe equipment operation. With various types, ratings, and specifications available in the market, making an informed choice requires careful evaluation of multiple technical and operational factors.

Understanding Power Transformer Specifications

Voltage Ratings and Transformation Ratio

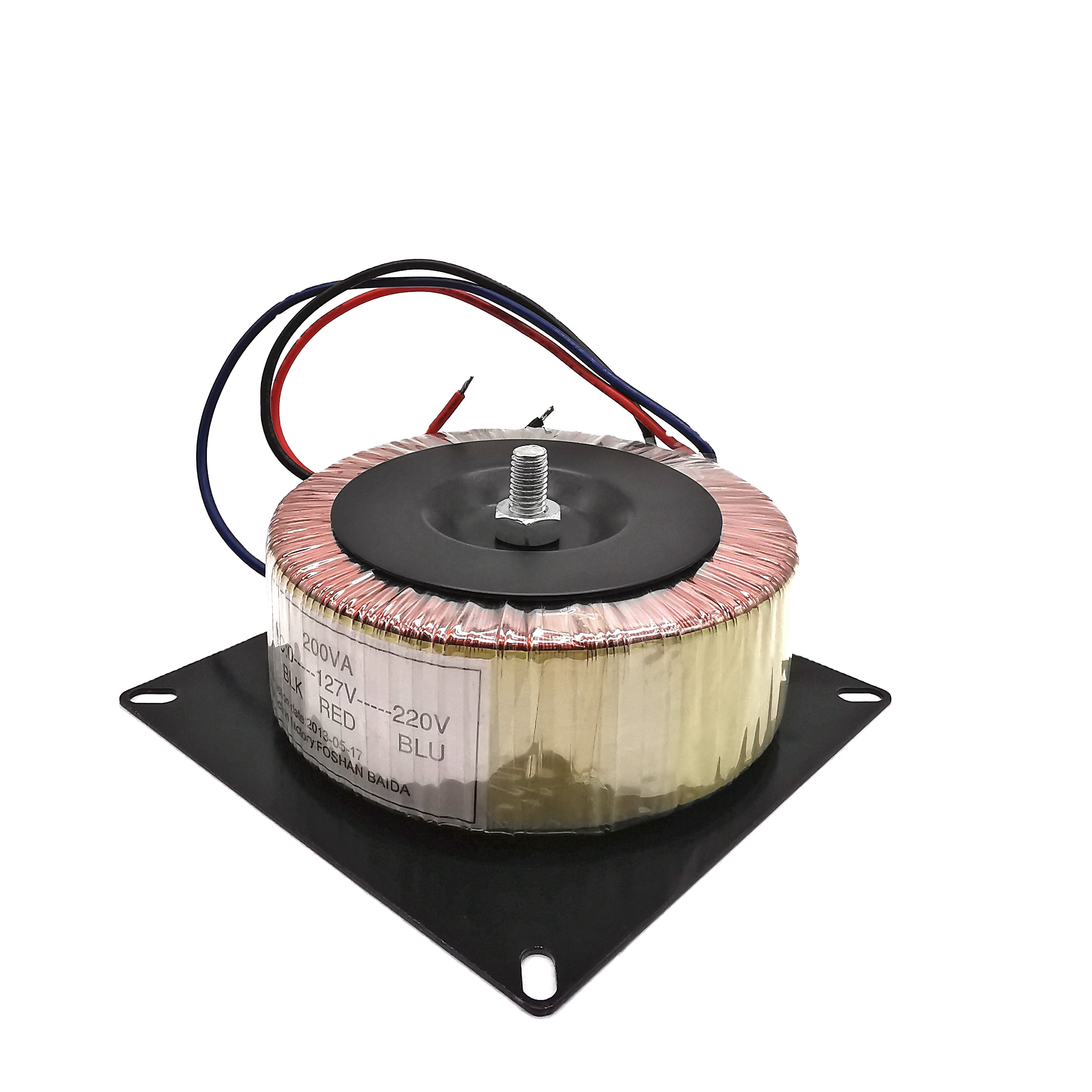

The primary consideration when selecting a power transformer is its voltage ratings. The transformation ratio, which defines the relationship between primary and secondary voltages, must precisely match your application requirements. Input voltage tolerance ranges and output voltage stability under varying loads are crucial factors that influence the transformer's performance in real-world conditions.

Modern power transformer designs incorporate advanced voltage regulation features to maintain stable output despite input fluctuations. This becomes particularly important in applications where sensitive electronic equipment requires consistent power supply parameters.

Power Rating and Load Capacity

A power transformer's KVA rating indicates its capacity to handle electrical loads. Selecting a transformer with appropriate power rating requires careful analysis of both current and future load requirements. Engineers typically recommend including a 20-30% capacity buffer to accommodate load growth and prevent overloading situations.

The continuous load rating must be evaluated alongside short-term peak load capabilities. Some applications may experience significant load variations, requiring transformers with robust overload capacity for brief periods while maintaining thermal stability.

Environmental and Installation Considerations

Operating Environment Assessment

The installation environment significantly impacts power transformer selection. Factors such as ambient temperature, humidity levels, altitude, and exposure to environmental elements must be carefully evaluated. Indoor installations may require different specifications compared to outdoor applications where transformers face harsh weather conditions.

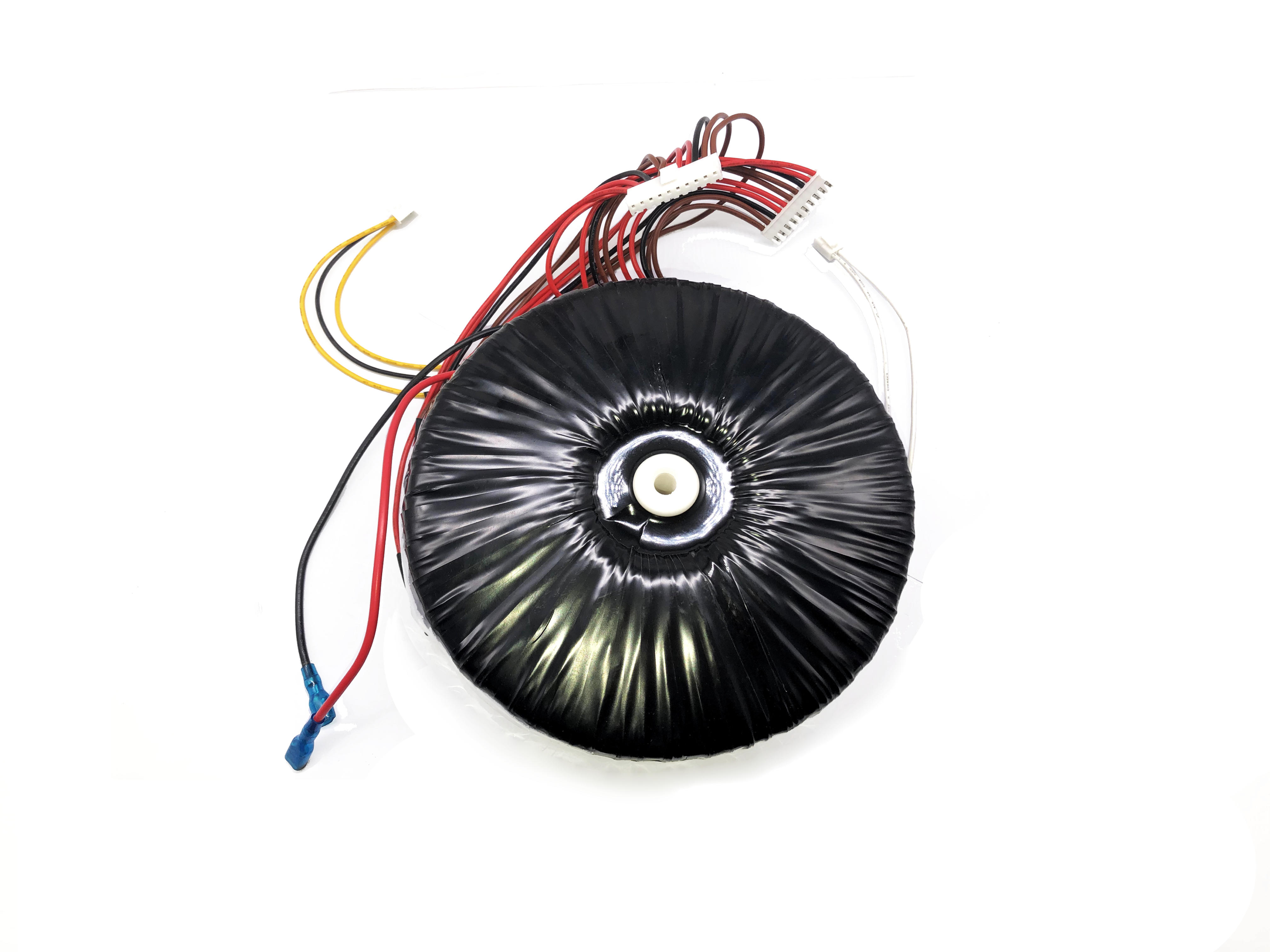

Temperature rise limitations and cooling system requirements depend on the operating environment. Oil-filled transformers offer excellent cooling properties but require additional safety measures, while dry-type transformers might be more suitable for indoor installations with space constraints.

Space and Installation Requirements

Physical dimensions, weight, and installation requirements play crucial roles in transformer selection. The available space must accommodate not only the transformer itself but also provide adequate clearance for ventilation, maintenance access, and safety compliance. Some installations may require special mounting arrangements or enclosure types based on location and environmental factors.

Consider future maintenance requirements when evaluating installation options. Easy access to monitoring points, cooling systems, and protective devices ensures efficient maintenance operations throughout the transformer's lifecycle.

Performance and Efficiency Characteristics

Energy Efficiency Standards

Modern power transformers must comply with increasingly stringent energy efficiency regulations. Core losses and copper losses contribute to the transformer's overall efficiency rating. High-efficiency designs may command premium prices but offer significant long-term energy cost savings.

The selection process should include evaluation of no-load losses and load losses under various operating conditions. Advanced core materials and winding designs can significantly improve efficiency, particularly in applications with variable load profiles.

Protection and Monitoring Features

Integrated protection features safeguard both the transformer and connected equipment. Temperature monitoring, overcurrent protection, and fault detection capabilities are essential considerations. Modern power transformers often include smart monitoring systems that provide real-time performance data and predictive maintenance alerts.

The protection scheme must align with your facility's overall power system coordination strategy. Consider compatibility with existing protection systems and communication protocols when selecting monitoring features.

Lifetime Cost Considerations

Initial Investment Analysis

While purchase price is important, it should not be the sole determining factor in power transformer selection. The total cost of ownership includes installation, maintenance, energy losses, and potential replacement costs. High-quality transformers often justify their premium price through superior reliability and efficiency.

Consider warranty terms, manufacturer support, and spare parts availability when evaluating different options. These factors significantly impact long-term ownership costs and maintenance strategies.

Maintenance and Reliability Factors

Regular maintenance requirements vary among different transformer types and designs. Some models offer extended service intervals and simplified maintenance procedures, reducing operational costs. Reliability track records and mean time between failures should influence the selection decision.

Advanced diagnostic features and condition monitoring capabilities can help optimize maintenance schedules and prevent unexpected failures. These features may add to initial costs but provide valuable long-term benefits through improved reliability.

Frequently Asked Questions

What is the typical lifespan of a power transformer?

A well-maintained power transformer typically lasts 20-35 years, depending on operating conditions, loading patterns, and maintenance practices. Some transformers in favorable conditions can operate reliably for over 40 years when properly maintained and not subjected to excessive stress.

How important is oversizing a power transformer?

While some oversizing is prudent to accommodate future growth, excessive oversizing can lead to higher losses and reduced efficiency. A general rule is to select a transformer rated 20-30% above current maximum demand, considering realistic growth projections.

Are there specific maintenance requirements for different transformer types?

Yes, maintenance requirements vary significantly between oil-filled and dry-type transformers. Oil-filled units require regular oil testing and possible filtering, while dry-type transformers typically need less maintenance but require careful environmental monitoring and regular cleaning to prevent dust accumulation.