Core Materials for Toroidal Transformers

Toroidal transformer cores are constructed from specialized magnetic materials to optimize performance. Below are the most widely used options:

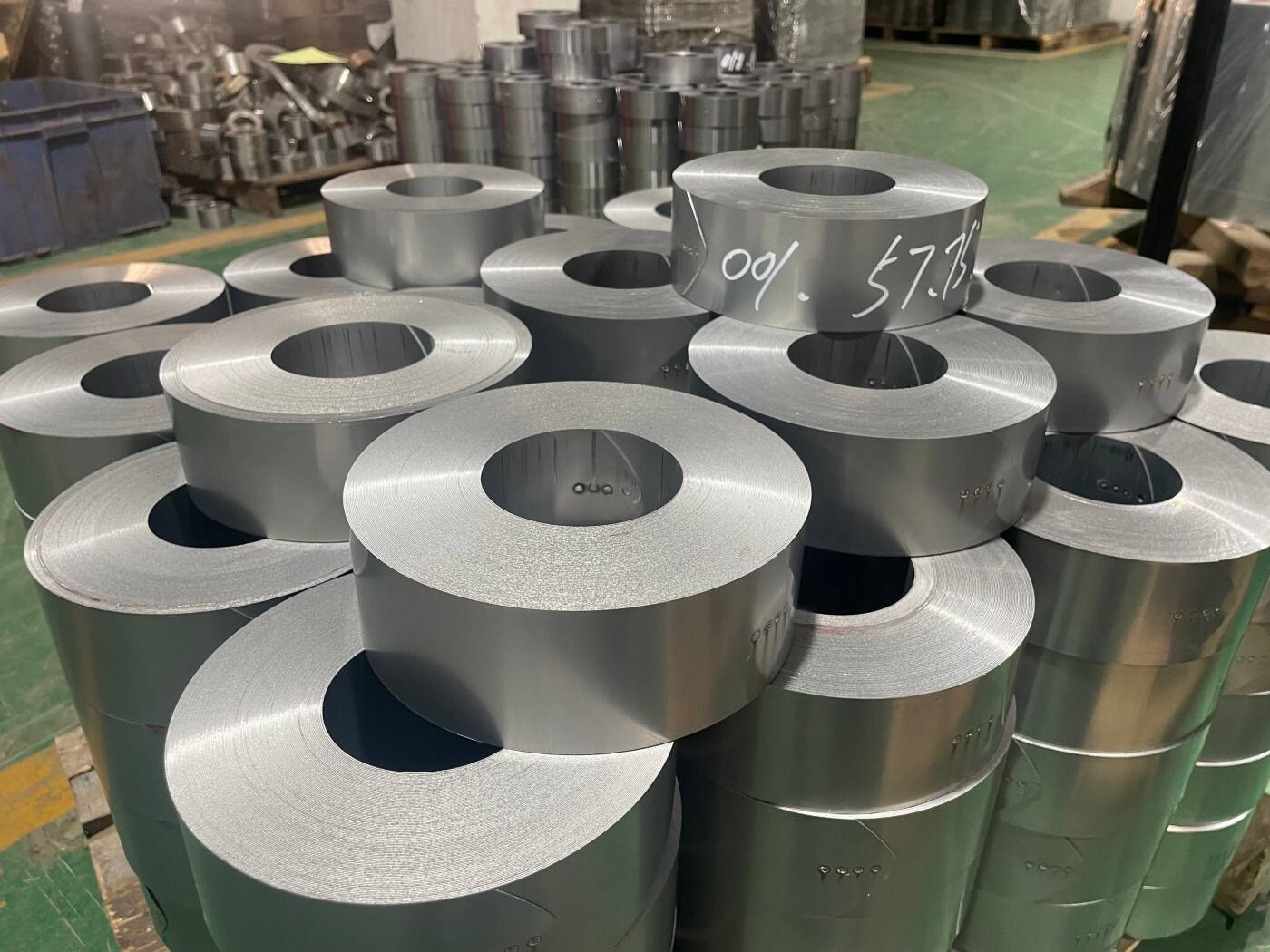

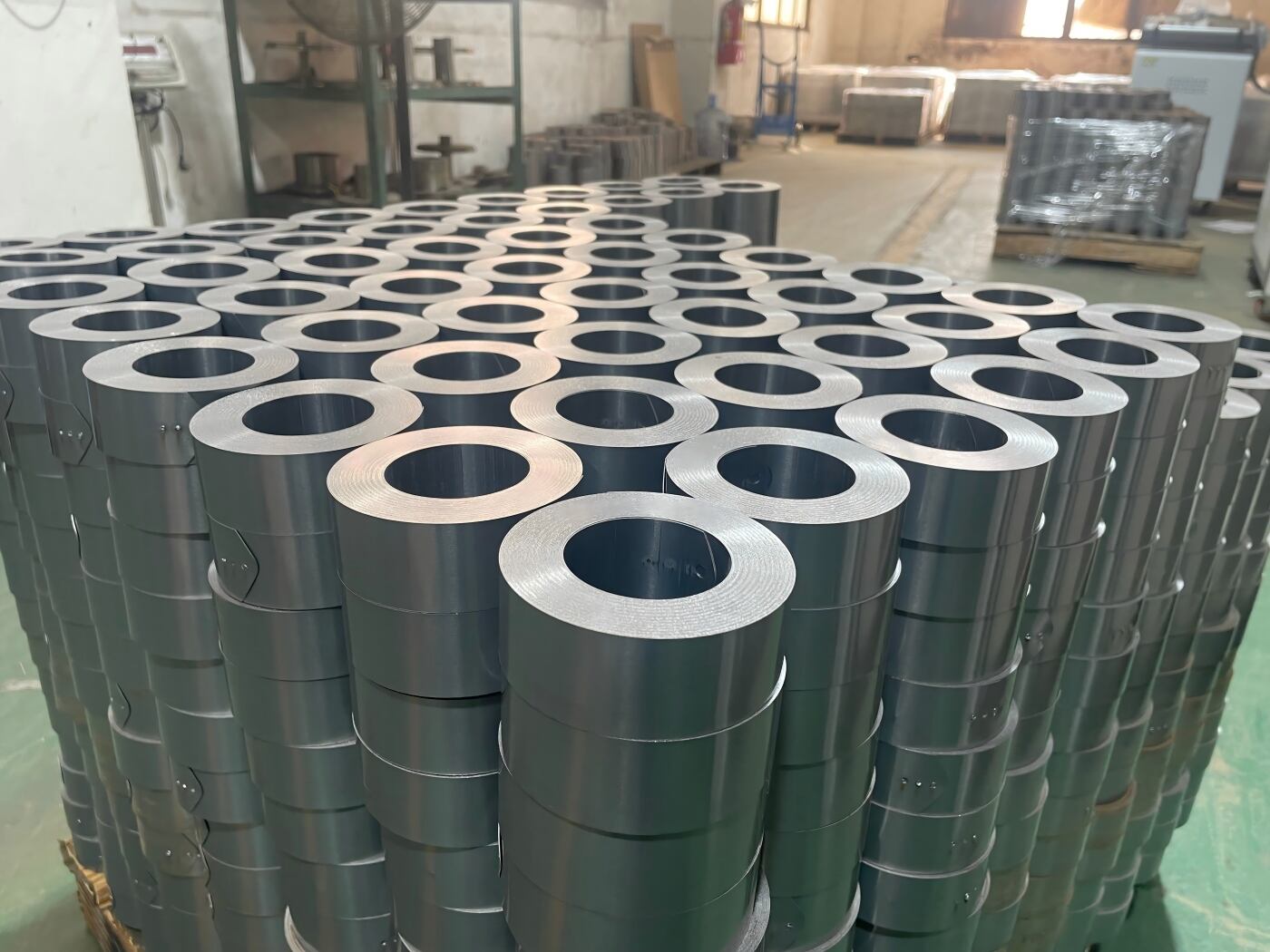

1. Silicon Steel (Electrical Steel)

Properties: Low magnetoresistance, high permeability, minimized hysteresis & eddy current losses.

Form Factor: Laminated sheets (0.3-0.35 mm thickness) stacked into annular shapes.

Applications: Ideal for high-efficiency, low-noise power transformers (50/60 Hz).

2. Nickel-Iron Alloys (e.g., Permalloy, MuMetal)

Properties: Ultra-high permeability (80,000), near-zero magnetostriction, exceptional DC bias tolerance.

Advantages: Superior performance in precision instruments and high-frequency (kHz-MHz) scenarios.

Use Cases: Aerospace sensors, telecom filters, medical imaging equipment.

3. Ferrite

Composition: Ceramic compounds (Fe₂O₃ + Mn/Zn/Ni oxides).

Key Features: High saturation flux density (0.3-0.5 T), minimal core loss at 20 kHz-1 MHz.

Applications: Switch-mode power supplies (SMPS), EV charging systems, RF transformers.

4. Iron Oxide (Fe₃O₄)

Emerging Tech: Nano-engineered cores with plasma-sprayed coatings.

Benefits: Enhanced high-frequency response (10 MHz), thermal stability up to 200°C.

Niche Uses: 5G infrastructure, quantum computing modules, microwave systems.