In the world of power supply design and electrical engineering, linear transformers have established themselves as the gold standard for applications demanding exceptional performance characteristics. These sophisticated electromagnetic devices have earned widespread recognition across industries for their ability to deliver consistent power conversion while maintaining minimal acoustic interference and exceptional operational reliability. Understanding the unique engineering principles behind linear transformers reveals why they continue to dominate critical applications where precision and dependability are paramount.

The fundamental design philosophy of linear transformers prioritizes smooth, continuous power delivery over switching efficiency, resulting in superior performance characteristics that make them indispensable in sensitive electronic applications. Their construction methodology and operational principles create inherent advantages that switching-mode alternatives often cannot match, particularly in environments where electromagnetic compatibility and long-term stability are critical requirements.

Core Design Principles Behind Low Noise Operation

Electromagnetic Field Management

The exceptional low-noise characteristics of linear transformers stem from their sophisticated electromagnetic field management systems. Unlike switching transformers that generate high-frequency harmonics during rapid switching operations, linear transformers operate at fixed frequencies, typically 50Hz or 60Hz, which corresponds to standard AC power grid frequencies. This consistent frequency operation eliminates the broad spectrum of electromagnetic interference commonly associated with switching power supplies.

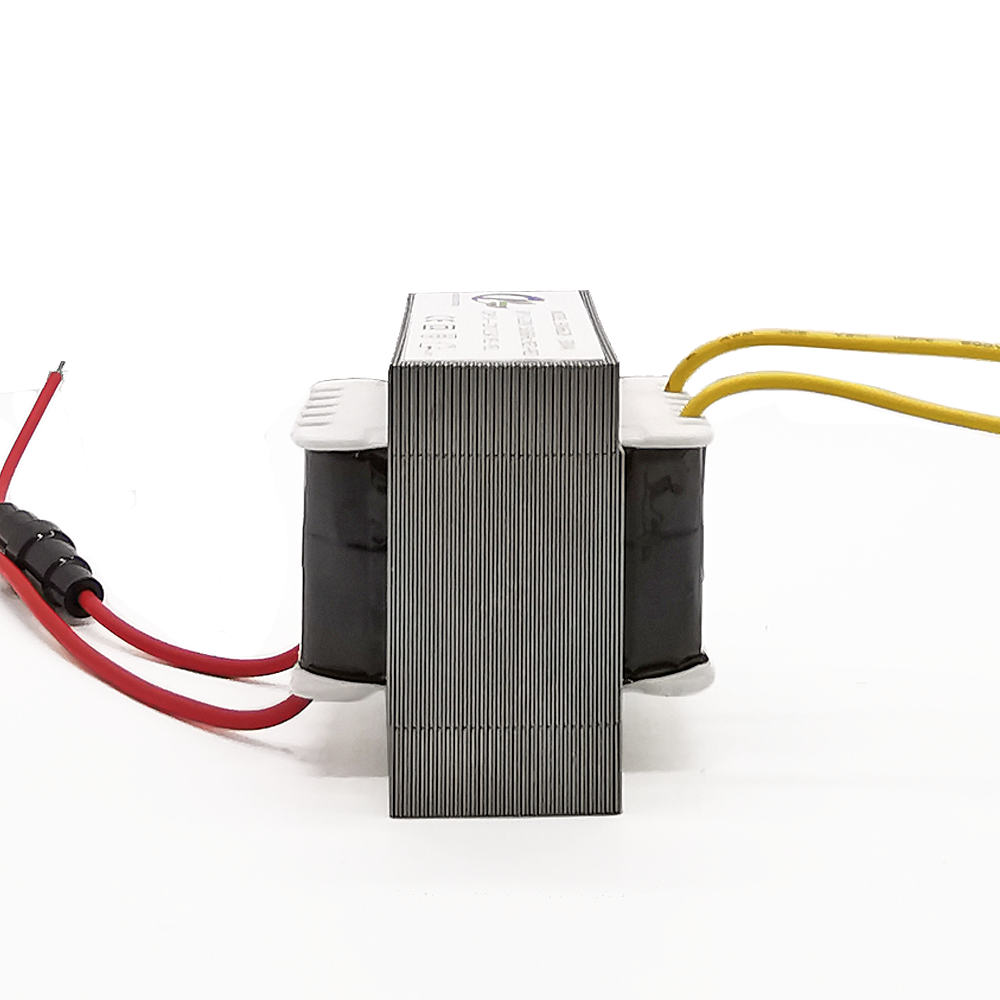

The core construction of linear transformers utilizes high-quality ferrite or silicon steel laminations that are precisely engineered to minimize magnetostriction effects. These magnetic materials are carefully selected and processed to reduce magnetic domain movement, which is a primary source of audible noise in electromagnetic devices. The laminated structure prevents eddy current formation while maintaining optimal magnetic flux density distribution throughout the core material.

Advanced winding techniques employed in linear transformers further contribute to noise reduction by maintaining proper wire tension and geometric alignment. The precise positioning of primary and secondary windings creates balanced electromagnetic fields that minimize mechanical vibrations and reduce acoustic emissions. This meticulous construction approach ensures that linear transformers maintain their quiet operation throughout their operational lifespan.

Thermal Stability and Heat Dissipation

Thermal management plays a crucial role in the low-noise operation of linear transformers. The continuous current flow in linear designs generates predictable heat patterns that can be effectively managed through proper thermal design. Unlike switching transformers that experience thermal cycling due to rapid on-off operations, linear transformers maintain steady-state thermal conditions that prevent material expansion and contraction cycles.

The encapsulation materials used in modern linear transformers are specifically formulated to provide excellent thermal conductivity while maintaining electrical insulation properties. These advanced polymer compounds help dissipate heat evenly across the transformer structure, preventing hot spots that could lead to material degradation and increased noise generation. The stable thermal environment ensures that magnetic materials maintain their optimal permeability characteristics throughout the operating temperature range.

Proper thermal design also contributes to the long-term reliability of linear transformers by preventing thermal stress on internal components. The gradual temperature variations experienced in linear operation allow materials to accommodate thermal expansion without creating mechanical stress points that could lead to premature failure or increased acoustic emissions.

Construction Methods That Enhance Reliability

Material Selection and Quality Control

The exceptional reliability of linear transformers begins with rigorous material selection processes that prioritize long-term stability over cost optimization. High-grade electrical steel or ferrite core materials undergo extensive testing to ensure consistent magnetic properties and minimal aging characteristics. These materials are selected based on their ability to maintain stable permeability values over extended operational periods, typically spanning decades of continuous operation.

Wire selection for linear transformers involves careful consideration of conductor purity, insulation quality, and thermal coefficient characteristics. High-purity copper conductors with precisely controlled grain structure provide optimal electrical conductivity while minimizing resistance changes over temperature variations. The insulation systems employ multiple layers of different dielectric materials to provide redundant protection against electrical breakdown and environmental degradation.

Quality control procedures for linear transformers typically involve comprehensive electrical, mechanical, and thermal testing protocols that exceed standard industry requirements. Each unit undergoes rigorous testing including insulation resistance measurements, partial discharge testing, and extended burn-in procedures to identify potential reliability issues before deployment. This thorough quality assurance process ensures that linear transformers consistently meet their specified reliability targets.

Manufacturing Precision and Assembly Techniques

The manufacturing processes used for linear transformers emphasize precision and consistency to achieve optimal reliability characteristics. Automated winding equipment ensures uniform wire tension and consistent layer-to-layer spacing, which minimizes internal stress concentrations that could lead to premature failure. The precise control of winding parameters also contributes to consistent electrical characteristics across production batches.

Assembly procedures for linear transformers incorporate multiple verification steps to ensure proper component alignment and secure mechanical connections. Core lamination stacking sequences are carefully controlled to minimize air gaps and ensure uniform magnetic field distribution. The clamping mechanisms used to secure core assemblies are designed to maintain consistent pressure over the transformer's operational lifetime, preventing mechanical loosening that could increase noise levels.

Advanced encapsulation techniques protect internal components from environmental contamination while providing mechanical support to prevent vibration-induced damage. The encapsulation materials are formulated to maintain their mechanical properties over wide temperature ranges and extended exposure to electrical stress. This comprehensive protection system significantly enhances the long-term reliability of linear transformers in demanding applications.

Performance Advantages in Critical Applications

Electromagnetic Compatibility Benefits

Linear transformers offer superior electromagnetic compatibility performance compared to switching alternatives, making them ideal for sensitive electronic applications. The absence of high-frequency switching components eliminates the generation of electromagnetic interference across broad frequency spectrums. This characteristic makes linear transformers particularly valuable in medical equipment, precision instrumentation, and communication systems where electromagnetic compatibility is critical.

The predictable electromagnetic signature of linear transformers simplifies system-level EMC design by eliminating the need for complex filtering networks typically required with switching power supplies. The low-frequency harmonic content produced by linear transformers can be easily managed through conventional filtering techniques without compromising system performance or adding significant cost and complexity to the overall design.

Linear transformers also demonstrate excellent immunity to electromagnetic interference from external sources due to their robust construction and shielding characteristics. The laminated core structure provides natural electromagnetic shielding, while the encapsulation materials can be formulated with conductive fillers to enhance RF immunity. This inherent EMI resistance ensures stable operation in electromagnetically challenging environments.

Power Quality and Regulation

The power quality characteristics of linear transformers set them apart from switching alternatives in applications requiring precise voltage regulation and minimal output ripple. Linear transformers provide excellent load regulation characteristics due to their continuous power transfer mechanism, which responds smoothly to load variations without introducing switching artifacts or transient disturbances.

The natural filtering characteristics of linear transformers help attenuate input voltage variations and provide clean, stable output power even under challenging input conditions. The inductive and capacitive elements inherent in linear transformer design create effective low-pass filtering that removes high-frequency noise and voltage spikes from the power supply output. This natural filtering capability reduces the need for additional external filtering components.

Linear transformers also provide excellent isolation between primary and secondary circuits, with isolation capabilities that can exceed several kilovolts depending on the specific design requirements. This high isolation capability is particularly important in medical applications, industrial control systems, and telecommunications equipment where safety and signal integrity are paramount considerations.

Industry Applications and Use Cases

Medical and Healthcare Equipment

The healthcare industry relies heavily on linear transformers for powering critical medical equipment where patient safety and operational reliability are non-negotiable requirements. Medical imaging systems, patient monitoring devices, and life support equipment utilize linear transformers to ensure stable, noise-free power delivery that won't interfere with sensitive diagnostic procedures or compromise patient care.

The low electromagnetic interference characteristics of linear transformers are particularly important in MRI systems and other sensitive medical imaging equipment where even minimal electrical noise can degrade image quality or create diagnostic artifacts. The predictable electromagnetic signature of linear transformers allows medical equipment designers to implement effective shielding strategies without adding excessive weight or complexity to portable medical devices.

Regulatory compliance in medical applications often requires extensive documentation of power supply characteristics and long-term reliability data. Linear transformers have established track records spanning decades of successful medical applications, providing the reliability documentation and performance history required for FDA approval and international medical device certifications.

Industrial Automation and Control Systems

Industrial automation systems depend on linear transformers to provide stable power for programmable logic controllers, sensor networks, and actuator systems that must operate reliably in harsh industrial environments. The robust construction and thermal stability of linear transformers make them ideal for continuous operation in manufacturing environments where downtime costs can be extremely high.

The excellent regulation characteristics of linear transformers ensure consistent performance of precision industrial equipment such as CNC machines, robotic systems, and quality control instrumentation. These applications require power supplies that maintain stable output voltages despite variations in input power quality and load conditions that are common in industrial settings.

Linear transformers also provide the high isolation capabilities required for industrial safety systems and hazardous area applications. The ability to provide several kilovolts of isolation while maintaining excellent power quality makes linear transformers essential components in industrial control systems that must meet stringent safety and reliability standards.

Comparative Analysis with Alternative Technologies

Linear vs Switching Power Supply Technologies

When comparing linear transformers to switching power supply alternatives, several key performance differences become apparent. While switching power supplies offer superior energy efficiency, linear transformers provide advantages in noise performance, electromagnetic compatibility, and long-term reliability that make them preferable for specific applications. The continuous power transfer mechanism of linear transformers eliminates the switching artifacts and electromagnetic interference inherent in switching designs.

The thermal characteristics of linear transformers differ significantly from switching alternatives, with linear designs producing steady-state heat loads that can be easily managed through conventional thermal design techniques. Switching power supplies experience thermal cycling due to their on-off operation, which can lead to thermal fatigue and reduced component lifespan over extended operational periods.

Maintenance requirements for linear transformers are typically lower than switching alternatives due to their simpler construction and fewer active components. The absence of semiconductor switching devices eliminates many potential failure modes and reduces the need for specialized maintenance procedures or replacement parts availability over the product lifecycle.

Cost-Benefit Analysis and Total Ownership

The initial cost comparison between linear transformers and switching alternatives often favors switching designs due to their lower material requirements and higher power density. However, total cost of ownership analysis frequently demonstrates the economic advantages of linear transformers in applications where reliability and longevity are important considerations.

The extended operational lifespan of linear transformers, often exceeding 20-30 years in properly designed applications, significantly reduces replacement and maintenance costs compared to switching alternatives that may require replacement every 5-10 years. The predictable failure modes and gradual degradation characteristics of linear transformers also enable better maintenance planning and reduced unexpected downtime costs.

System-level cost considerations often favor linear transformers in applications requiring extensive electromagnetic interference filtering or high isolation capabilities. The additional components and design complexity required to achieve comparable EMC performance with switching power supplies can offset their initial cost advantages while adding system complexity and potential reliability concerns.

FAQ

What makes linear transformers quieter than switching power supplies

Linear transformers operate at fixed frequencies (typically 50-60Hz) without the high-frequency switching that generates electromagnetic interference in switching power supplies. Their laminated core construction and precise winding techniques minimize magnetostriction effects and mechanical vibrations, resulting in significantly lower acoustic emissions. The continuous power transfer mechanism eliminates switching artifacts and transient noise that characterize switching designs.

How do linear transformers achieve superior reliability compared to other power conversion technologies

The exceptional reliability of linear transformers stems from their simple construction with fewer active components, high-quality materials selection, and steady-state thermal operation. Unlike switching power supplies that experience thermal cycling and component stress from rapid on-off operations, linear transformers maintain consistent operating conditions that prevent premature component degradation. Their proven design principles and extensive operational history demonstrate reliability characteristics that often exceed 20-30 years in properly designed applications.

In which applications are linear transformers most beneficial

Linear transformers excel in applications requiring low electromagnetic interference, high reliability, and excellent power quality characteristics. They are particularly valuable in medical equipment, precision instrumentation, sensitive communication systems, and industrial control applications where noise performance and long-term stability are critical. Their superior isolation capabilities and predictable electromagnetic characteristics make them ideal for safety-critical systems and electromagnetically sensitive environments.

What are the main disadvantages of linear transformers compared to switching alternatives

The primary disadvantages of linear transformers include lower energy efficiency, larger physical size, and higher weight compared to switching power supplies. They also generate more heat due to continuous power dissipation and may have higher initial costs for applications not requiring their specific performance advantages. However, these disadvantages are often offset by their superior reliability, lower electromagnetic interference, and reduced total cost of ownership in appropriate applications.

Table of Contents

- Core Design Principles Behind Low Noise Operation

- Construction Methods That Enhance Reliability

- Performance Advantages in Critical Applications

- Industry Applications and Use Cases

- Comparative Analysis with Alternative Technologies

-

FAQ

- What makes linear transformers quieter than switching power supplies

- How do linear transformers achieve superior reliability compared to other power conversion technologies

- In which applications are linear transformers most beneficial

- What are the main disadvantages of linear transformers compared to switching alternatives