Understanding the Fundamental Distinctions of Transformer Frequencies

In the realm of electrical engineering and power distribution, transformers play a pivotal role in voltage conversion and power transfer. The frequency at which a transformer operates significantly impacts its design, efficiency, and applications. The distinction between high frequency and low frequency transformers represents a crucial consideration for engineers and industry professionals when selecting the appropriate equipment for specific applications.

The evolution of transformer technology has led to specialized designs optimized for different frequency ranges, each offering unique advantages and limitations. By understanding these transformer frequency differences, professionals can make informed decisions that enhance system performance and reliability while ensuring cost-effective solutions for their specific needs.

Core Construction and Material Properties

Magnetic Core Materials and Their Characteristics

High frequency transformers typically utilize advanced magnetic materials such as ferrite cores, which excel at minimizing eddy current losses at higher frequencies. These materials maintain their magnetic properties even at frequencies reaching hundreds of kilohertz or megahertz. In contrast, low frequency transformers commonly employ silicon steel or electrical steel laminations, which are optimized for operation at power line frequencies of 50 or 60 Hz.

The selection of core materials directly influences the transformer's efficiency and performance. Ferrite cores in high frequency applications offer lower core losses and better temperature stability, while silicon steel cores provide excellent magnetic properties at lower frequencies and higher power levels.

Core Size and Weight Considerations

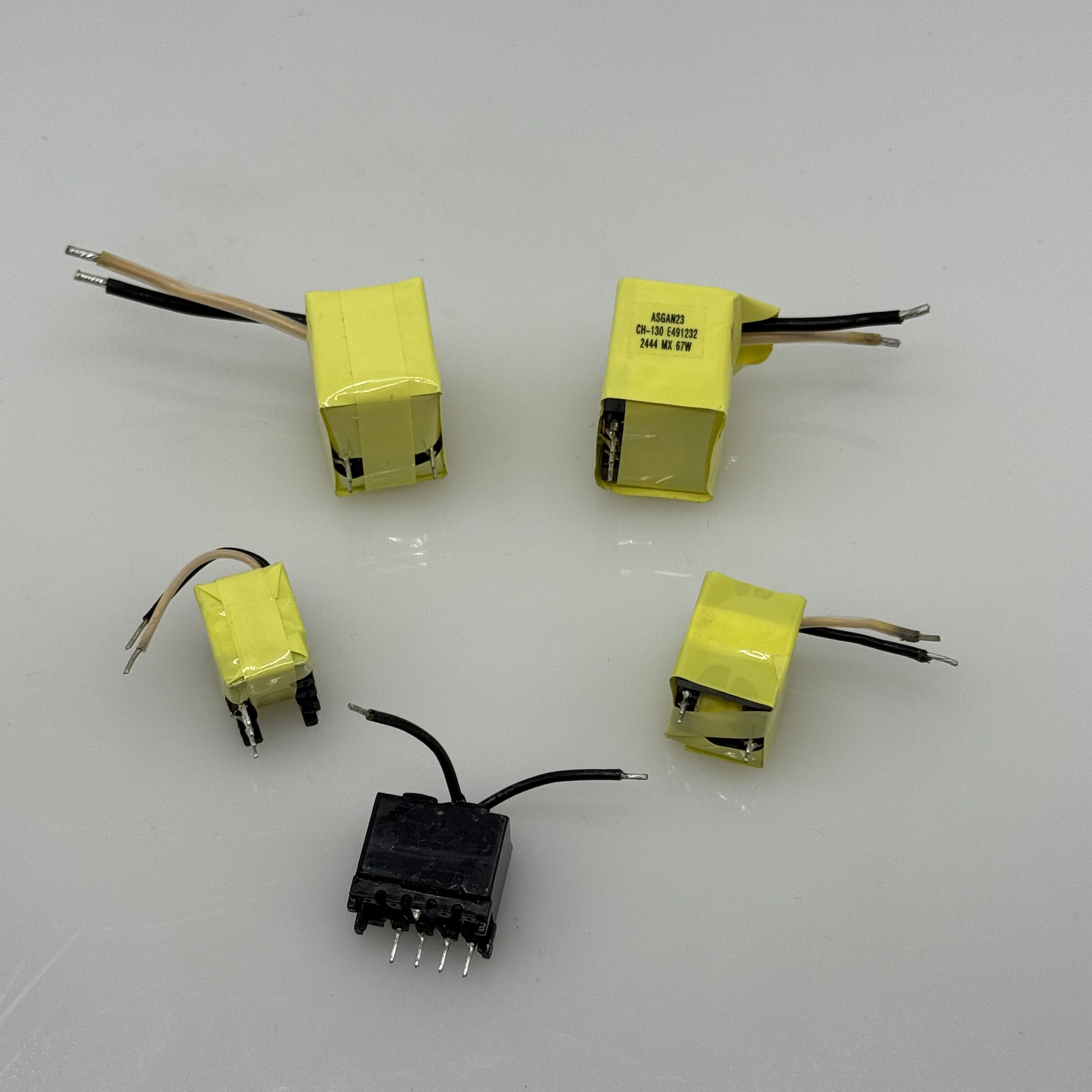

One of the most notable transformer frequency differences appears in the physical dimensions of the cores. High frequency transformers can be significantly smaller and lighter than their low frequency counterparts for the same power rating. This size reduction is possible because the core's cross-sectional area can be decreased as frequency increases while maintaining the same magnetic flux density.

The compact size of high frequency transformers makes them ideal for modern electronic devices and space-constrained applications. Low frequency transformers, while larger, offer robust performance and reliability in traditional power distribution systems.

Winding Design and Configuration

Conductor Selection and Arrangement

The winding design varies significantly between high and low frequency transformers. High frequency applications must address skin effect and proximity effect, which become more pronounced as frequency increases. This often necessitates the use of Litz wire or specialized conductor configurations to minimize AC resistance and associated losses.

Low frequency transformers typically employ solid conductors or parallel strands, as the skin effect is less significant at power frequencies. The winding arrangement focuses more on voltage isolation and thermal management rather than high-frequency effects.

Parasitic Effects and Their Management

Parasitic capacitance and leakage inductance present greater challenges in high frequency transformer design. Engineers must carefully consider winding geometry and spacing to minimize these effects, often employing interleaved winding techniques and specialized insulation methods.

For low frequency transformers, these parasitic effects have less impact on performance, allowing for simpler winding configurations and more straightforward design approaches. However, attention must still be paid to ensuring proper voltage isolation and thermal management.

Applications and Performance Characteristics

Power Handling Capabilities

Low frequency transformers excel in high-power applications, commonly handling power levels from kilowatts to megawatts in utility distribution systems, industrial equipment, and large-scale power conversion. Their robust construction and proven design principles make them ideal for these demanding applications.

High frequency transformers typically operate at lower power levels, ranging from watts to kilowatts. They find extensive use in switch-mode power supplies, DC-DC converters, and modern electronic devices where size and weight constraints are critical factors.

Efficiency and Loss Characteristics

The efficiency profiles of high and low frequency transformers differ significantly. High frequency designs can achieve excellent efficiency through reduced core size and optimized materials, but they must carefully manage high-frequency losses. These transformers require special attention to switching losses and electromagnetic interference (EMI) considerations.

Low frequency transformers benefit from well-established design practices and materials optimized for power frequencies. While they may be larger, they can achieve very high efficiencies in power distribution applications, with losses primarily dominated by core and copper losses.

Cost and Manufacturing Considerations

Production Complexity and Materials

Manufacturing processes for high frequency transformers often require more specialized techniques and precision. The use of advanced core materials, Litz wire, and complex winding configurations can increase production costs. However, the smaller size typically results in reduced material usage per unit.

Low frequency transformers generally involve more straightforward manufacturing processes but require larger quantities of core and conductor materials. The mature technology and established production methods often lead to more competitive pricing for standard power applications.

Maintenance and Lifetime Expectations

The maintenance requirements and expected lifetime of transformers vary with their frequency range. Low frequency power transformers are designed for decades of reliable operation with proper maintenance, often lasting 25-40 years in utility applications. Their robust construction and simple design principles contribute to their longevity.

High frequency transformers, while generally reliable, may have shorter operational lifetimes due to the more demanding operating conditions and complex construction. However, their application in modular electronic systems often allows for easier replacement when necessary.

Frequently Asked Questions

How do operating temperatures differ between high and low frequency transformers?

High frequency transformers typically operate at lower temperatures due to their smaller size and better thermal management capabilities. Low frequency transformers may generate more heat due to their larger core size and higher power handling, requiring more extensive cooling systems in some applications.

Can a high frequency transformer be used in low frequency applications?

While technically possible, using a high frequency transformer at low frequencies is generally impractical and inefficient. The core materials and winding designs are optimized for specific frequency ranges, and operating outside these ranges can result in poor performance and potential damage.

What role does frequency play in transformer size reduction?

Higher operating frequencies allow for smaller transformer sizes because the required core cross-sectional area is inversely proportional to frequency. This relationship enables significant size and weight reductions in high frequency transformers while maintaining the same power handling capability.

How do EMI considerations differ between high and low frequency transformers?

EMI considerations are much more critical in high frequency transformer design, requiring careful attention to shielding and winding arrangements. Low frequency transformers generally have fewer EMI concerns due to their lower operating frequencies, though proper shielding may still be necessary in sensitive applications.